Features

Gelgoog provides customers with the most suitable juice processing plant solution for apple,orange,mango,carrot,banana.

More than just machinery and equipment, we can also customize the machine and production solutions and the design of the juice line plant according to the customer's details.

More than just machinery and equipment, we can also customize the machine and production solutions and the design of the juice line plant according to the customer's details.

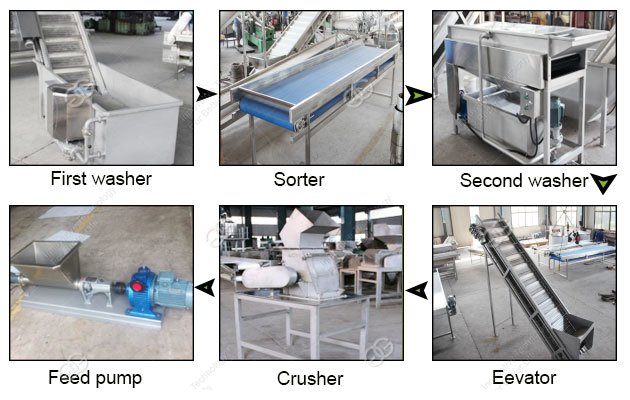

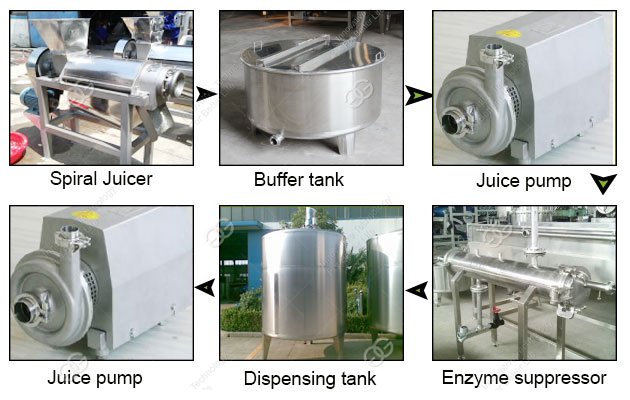

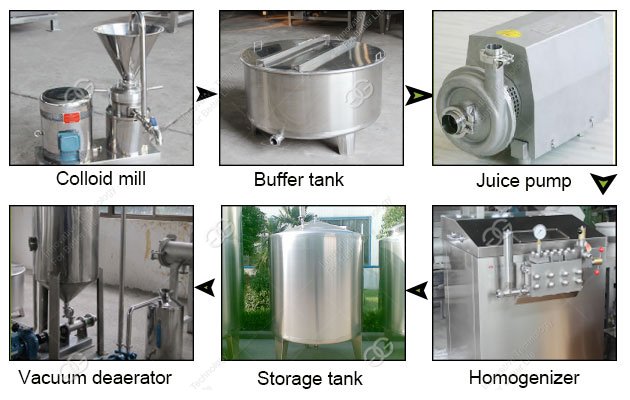

The following is the apple juice production line flow chart. We offer customized services based on customer rawmaterial materials and capacity requirements.

Raw material(Apple) - → elevator machine - → brush cleaning machine - → surf type washing machine - → stainless steel roller type inspection spray conveyor - → elevator - → hammer crusher - → low storage tank - → belt propeller single screw pump - → spiral juicer - → low storage tank - → stamping juice pump - → storage tank - → pump →Outgassing device - → sterilization machine - → filling line

In addition, we also offer other juice fruit production lines, such as:

Apple pulp production line

Mango juice processing plant

Banana pulp production line

Carrot juice extractor machine

Carrot juice extractor machine

Pineapple juice production line

Orange juice processing line

Orange juice processing line

Contact us for your juice business.

We use new technologies and new processes to optimize the combination of machinery with the best industrial technology data, making the equipment layout more scientific and reasonable. Its characteristics are reflected in: low disposable equipment investment; excellent fruit juice equipment manufacturing quality and engineering installation quality, ensuring the entire system process is reasonable, compact structure, beautiful appearance, stable operation, low operating and maintenance costs.

Technical Data

| Machine Name | Machine Size(mm) | Power(Kw) |

| Bubble type washing machine | 2600×1000×1600 | 4.75 |

| Sorting machine | 3500×1000×1200 | 0.75 |

| Brush type cleaning machine | 2500×700×1100 | 0.75 |

| Plate hoist | 3000×900×2000 | 0.75 |

| Hammer crusher | 1050×750×1800 | 4.00 |

| Forced feed pump | 1500×370×420 | 1.50 |

| Spiral fruit juicer | 1580×420×1400 | 4.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Preheater | 1500×460×1100 | 0.00 |

| Enzymatic hydrolysis tank | Φ1200×1900 | 1.50 |

| Juice pump | 400×300×350 | 0.75 |

| Plate and frame filter | 600×300×500 | 0.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Diatomaceous earth filter | 950×300×420 | 0.00 |

| Mixing tank | Φ1450×2300 | 2.20 |

| Juice pump | 400×300×350 | 0.75 |

| High pressure homogenizer | 1300×1100×1300 | 22 |

| Juice storage tank | Φ1450×2000 | 0 |

| Vacuum degasser | 1850×1000×2300 | 1.5 |

| Sterilizer machine | 2000×1200×2000 | 5 |

| Fruit juice finished can | Φ1450×2000 | 0 |