Features

For the apple and pear, we can provide juice extraction machine. The fruit juice extractor machine can process 0.5T/H,1.5T/H,2.5T/H and more. We also can provide you whole apple and pear juice line.

Apple and pear juice making machine introduction:

Apple and pear juice making machine introduction:

- The apple was crushed using a stainless steel crusher. These apple pieces are then immediately loaded into a apple juice machine.

- The apple juice extraction machine is suitable for the extraction of fruits and vegetables such as apple,pear,pineapple, carrot, cactus, etc. It has the functions of crushing, juicing and slagging.

- The parts in contact with the materials are made of stainless steel, which meets the food hygiene standards.

- Screens with different apertures can be selected according to the characteristics of the materials

- Easy operation and easy maintenance.

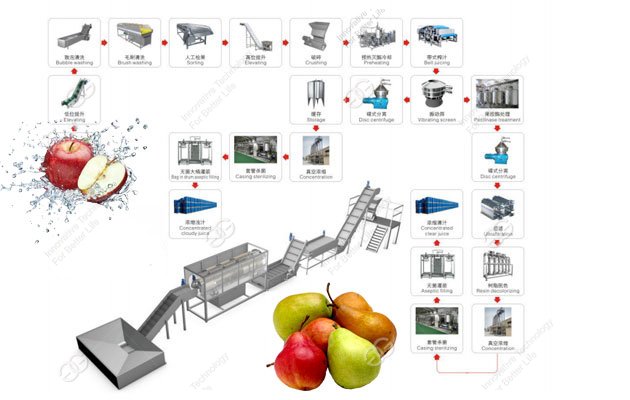

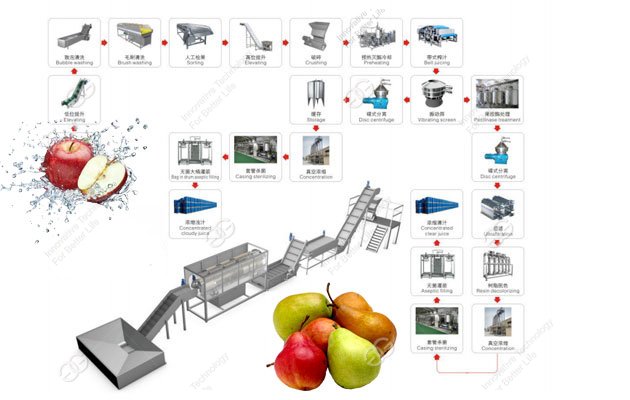

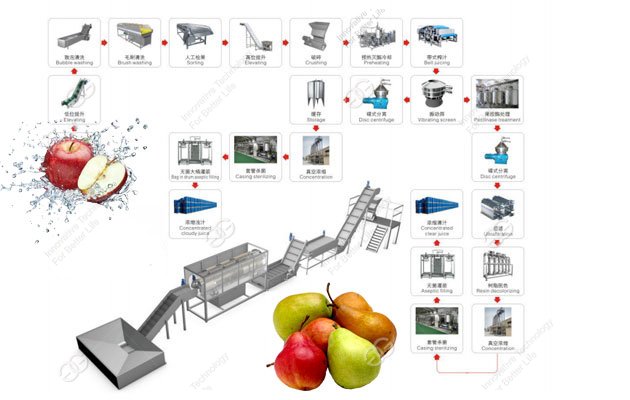

There are two type apple juicer machine .Both of them process step are similar, including fruit sorting, washing, juicing, clarification/homogenization, mixing, sterilization, filling and cooling. The difference between them is a process. A turbid juice was prepared by homogenization and a clarified juice was prepared by clarification. You can tell which type juice you need process.

Apple and pear juice processing plant equipment:

· Apple washing machine

· Broken juicer

· Apple pulper

· Juice homogenizer

· Juice filter

· Bottle filling machine

· Sterilizer

Leave message or contact us freely for your apple pear juice business. We will provide you whole fruit juice solution and help you get success in the fruit juice business.

Leave message or contact us freely for your apple pear juice business. We will provide you whole fruit juice solution and help you get success in the fruit juice business.

Technical Data

| Apple and Pear Juice Processing Machine | ||

| Machine Name | Machine Size(mm) | Voltage(Kw) |

| Bubble type washing machine | 2600×1000×1600 | 4.75 |

| Sorting machine | 3500×1000×1200 | 0.75 |

| Brush type cleaning machine | 2500×700×1100 | 0.75 |

| Plate hoist | 3000×900×2000 | 0.75 |

| Hammer crusher | 1050×750×1800 | 4.00 |

| Forced feed pump | 1500×370×420 | 1.50 |

| Spiral fruit juicer | 1580×420×1400 | 4.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Enzyme killer | 1500×460×1100 | 0.00 |

| Enzymatic hydrolysis tank | Φ1200×1900 | 1.50 |

| Juice pump | 400×300×350 | 0.75 |

| Plate and frame filter | 600×300×500 | 0.00 |

| Temporary storage tank | Φ1000×600 | 0.00 |

| Juice pump | 400×300×350 | 0.75 |

| Diatomaceous earth filter | 950×300×420 | 0.00 |

| Mixing tank | Φ1450×2300 | 2.20 |

| Juice pump | 400×300×350 | 0.75 |

| High pressure homogenizer | 1300×1100×1300 | 22 |

| Juice storage tank | Φ1450×2000 | 0 |

| Vacuum degasser | 1850×1000×2300 | 1.5 |

| Sterilizer machine | 2000×1200×2000 | 5 |

| Fruit juice finished can | Φ1450×2000 | 0 |