Features

The use of food drying machine is very common and indispensable in daily life. Due to the existence of food drying machine, humans have solved the problem that food cannot be stored for too long, and at the same time solved the problem of inconvenience in transportation.

Our heat pump drying machine can save 80% of the energy source. As a supplier of dried fruit food processing equipment manufacturer, we provide heat pump drying machine or dehydrators for various food and agricultural processes. For dried food and fruits, we have our own solutions to provide customers with implementation methods and suitable material processing procedures.

In the process of processing dried food, food dehydration machine is a very important equipment. The food dehydration machine affects the quality of the finished fruit.

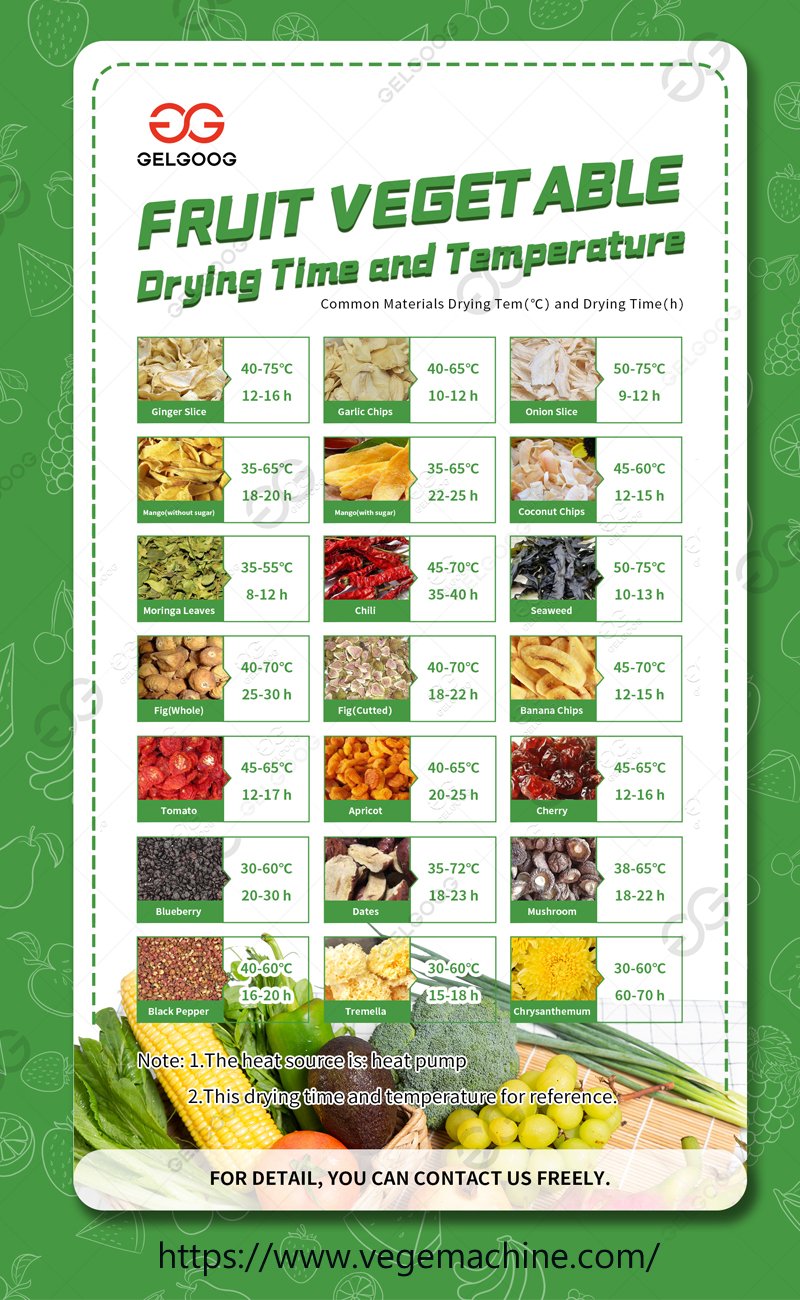

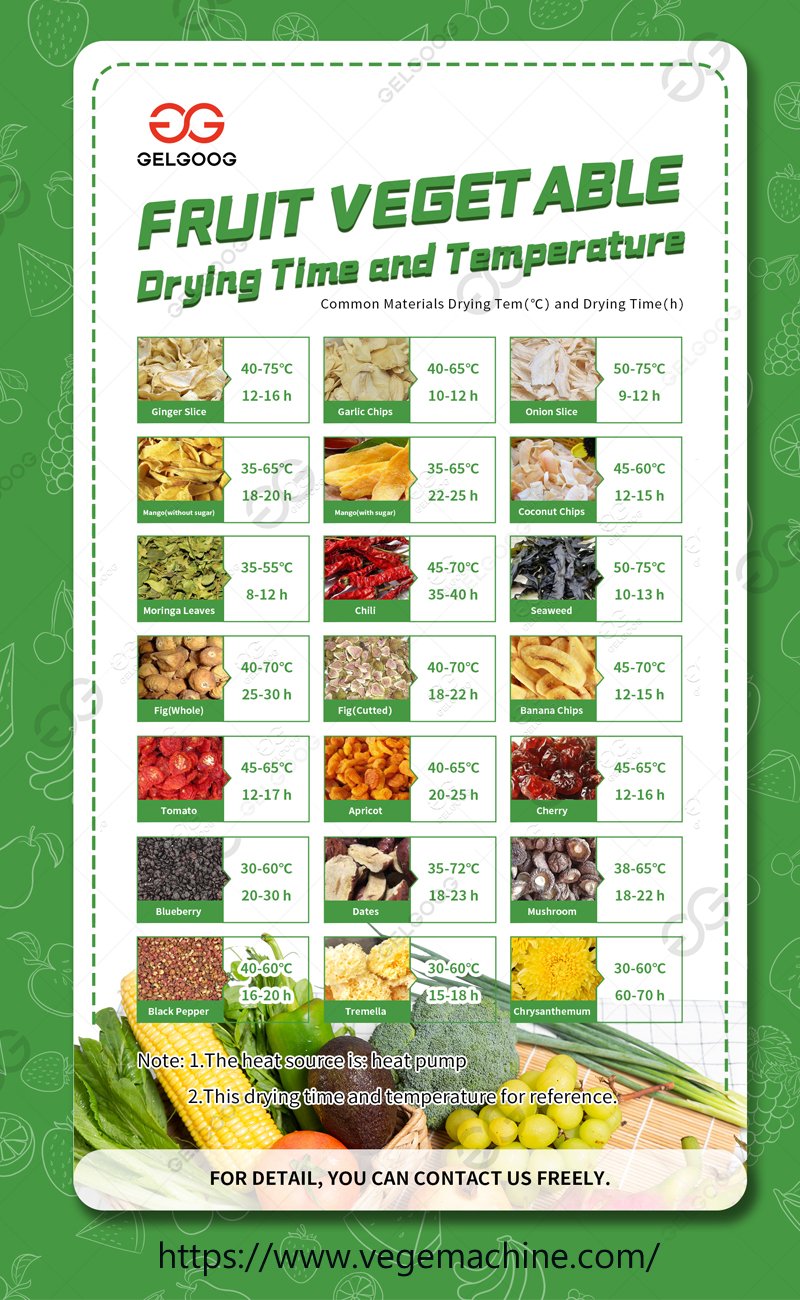

This is different processing time and temperature for different fruits and vegetables. Hope to help your drying business. If you need it, you can also download it for your convenience.

This is different processing time and temperature for different fruits and vegetables. Hope to help your drying business. If you need it, you can also download it for your convenience.

Our heat pump food dehydration machine has the following features:

- Improve product quality: For food processed by our heat pump dehydration machine, the quality of the food after drying is adjusted to be higher, and the drying is even.

- The temperature and humidity can be changed for drying: During the use of the heat pump drying machine, we can change the temperature and humidity settings. Adjust temperature and humidity according to specific fruit and vegetable materials. Heat pump dehydration machine can achieve excellent control of drying conditions.

- Energy recovery (improving efficiency): The biggest advantage of heat pump dehydration machine is that energy can be recovered, which greatly improves the utilization rate of thermal dreams, saves energy, and helps customers save energy costs;

Dried finished product display by heat hemp dehydration machine:

What kind of heat pump dehydration machine should be selected:

There are many kinds of dehydration machine on the market. The research and development of our heat pump dehydration machine has helped customers solve the waste of heat source.

The heat pump dehydration machine uses the principle of reverse Carnot cycle to absorb heat from the air and transfer it to the room, thereby increasing the temperature in the drying room, and cooperating with fans and other equipment to achieve drying of materials. In this way of heat transfer, our heat pump dehydration machine can save 80% of energy compared to other general drying equipment. Being in a large food drying factory, long-term operation saves a lot of costs.

The principle of heat pump dehydration machine:

The heat pump is mainly composed of condenser, compressor, throttle valve, condenser, compressor and other devices to form a circulation system.

The refrigerant circulates in the drying system under the action of the compressor, and the liquid refrigerant absorbs the heat in the environment in the evaporator and quickly evaporates and transforms into a gaseous state;

The gaseous refrigerant is compressed in the compressor and enters the condenser. The refrigerant enters the condenser and releases high-temperature heat to heat the air in the drying room. At the same time, it is cooled and converted into liquid;

The liquid refrigerant enters the evaporator again to absorb heat and convert it into gas.

The air around the condenser continuously transfers heat to the refrigerant. The circulation of the refrigerant realizes the continuous transfer of the heat in the air to the drying room.

Heat hemp dehydration machine working video show:

Technical Data

| 7P heat pump drying machine parameters | ||

| Item | Parameter | Unit |

| Environment temperature | 15-43 | ℃ |

| Drying temperature range | 30-75 | ℃ |

| Rated power | 12 | Kw |

| Maximum power | 18 | Kw |

| Power supply form | 380/3/50 | V/Ph/Hz |

| Temperature control accuracy | ±1 | ℃ |

| Electric heating power | 6 | Kw |

| Controller | Single chip microcomputer/PLC+color screen control | |

| Noise level | ≤75 | dB(A) |

| Capacity | 300-700 | Kg |

| Dehydration capacity | 21 | Kg/h(=50℃,80%) |